Environmental Impact of the Petroleum Industry

|

Exploration

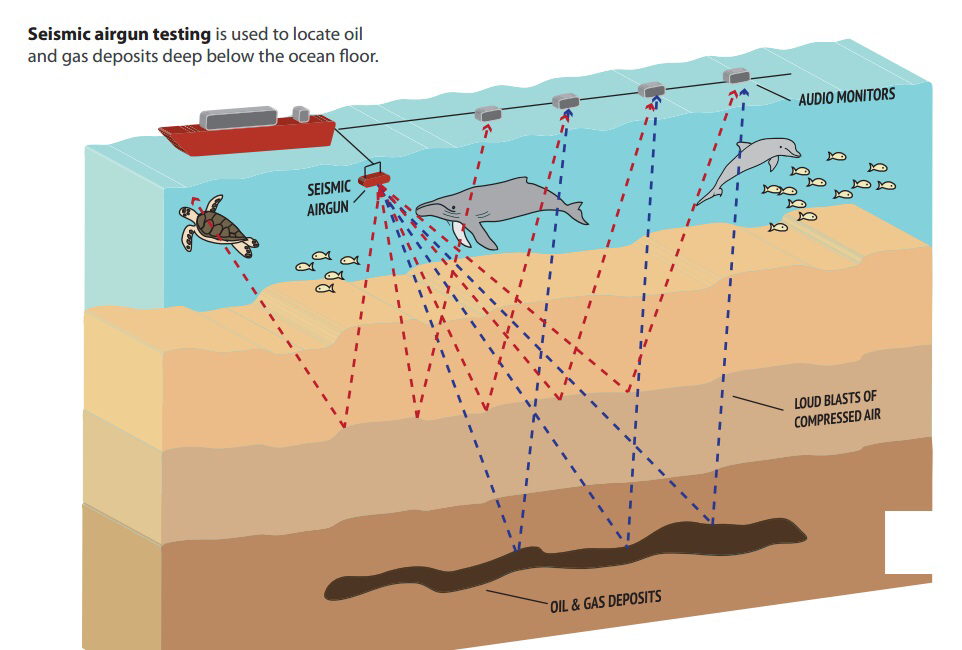

Operators investigate the likelihood of hydrocarbons being present under the seabed using high intensity sound (seismic surveys). Commercial fish species are sensitive to sound and, at close range, larval fish might even be killed by seismic sources. Seismic surveys might therefore disturb spawning fish away from territory where they have chosen to aggregate for spawning purposes and this could, in extreme circumstances, be harmful to stock productivity. Disturbing fish away from traditional areas may also affect fishermen’s catches. |

Drilling

During drilling, a drilling mud is continuously circulated between the well and the

platform through a ‘riser pipe’. Mud is used to maintain well pressure and wall stability, to cool

and lubricate the drill bit and to carry the rock chips (cuttings) generated during the drilling

process away from the cutting head to the platform. Here, the cuttings are partially cleaned and

the majority of drill mud re-used. Muds come in a variety of forms, dependent on their fluid base.

Amongst these are water based muds (WBM) and oil based muds (OBM). In the past, the bulk

of cleaned OBM cuttings were discharged to the seabed along with their residual oily mud

contamination. Extensive monitoring studies showed that this caused changes to the seabed via

a combination of smothering, organic enrichment and toxicity effects. These were seen to be

most severe close to discharging platforms where the ‘pile proper’ formed, but they commonly

extended up to a distance of 1 or 2 km. These discharges are no longer allowed.

Production

During production, large amounts of produced water (PW) are recovered with the

hydrocarbons. This is cleaned to very stringent standards and some is re-injected to maintain

reservoir pressure. The bulk, however, has traditionally been discharged to sea. As fields age

and as the amounts of oil remaining fall, the amounts of PW increase. The turn of the millennium

marked the time of maximum recovery of oil in the UK North Sea fields. So although the levels of

oil in produced water are very low, and despite improvements in technology which have tended

to reduce them, the overall total amount of oil discharged with the water by UK industry will

continue to rise in the next few years; it will then tail off as the industry declines. Increased

regulatory attention is therefore being focussed on the PW discharge, not least because in

addition to oil, it contains residues of naturally occurring heavy metals and radionuclides and oil

field chemicals.

Environmental hazards of petroleum refineries

Refineries are generally considered a major source of pollutants in areas where they are

located and are regulated by a number of environmental laws related to air, land and water.

Some of the regulations that affect the refining industry include the Clean Air Act, the Clean

Water Act, the Safe Drinking Water Act, CERCLA (i.e. Superfund: Comprehensive Environmental

Response, Compensation, and Liability Act), Emergency Planning and Community Right-to-

Know (EPCRA), OSHA (Occupational Safety & Health Administration), TSCA (Toxic Substances

Control Act), Oil Pollution Act and Spill Prevention Control and Countermeasure Plans. Here is a

breakdown of the air, water, and soil hazards posed by refineries:

• Air pollution hazards :

Petroleum refineries are a major source of hazardous and toxic air pollutants

such as BTEX compounds (benzene, toluene, ethylbenzene, and xylene). They are also

a major source of criteria air pollutants: particulate matter (PM), nitrogen oxides (〖NO〗_x),

carbon monoxide (CO), hydrogen sulfide (H_2 S), and sulfur dioxide (〖SO〗_2). Refineries

also release less toxic hydrocarbons such as natural gas (methane) and other light

volatile fuels and oils. Some of the chemicals released are known or suspected cancer-causing

agents, responsible for developmental and reproductive problems. They may

also aggravate certain respiratory conditions such as childhood asthma. Along with the

possible health effects from exposure to these chemicals, these chemicals may cause

worry and fear among residents of surrounding communities. Air emissions can come

from a number of sources within a petroleum refinery including: equipment leaks (from

valves or other devices); high-temperature combustion processes in the actual burning

of fuels for electricity generation; the heating of steam and process fluids; and the

transfer of products. Many thousands of pounds of these pollutants are typically emitted

into the environment over the course of a year through normal emissions, fugitive

releases, accidental releases, or plant upsets. The combination of volatile hydrocarbons

and oxides of nitrogen also contribute to ozone formation, one of the most important air

pollution problems in the United States.

During drilling, a drilling mud is continuously circulated between the well and the

platform through a ‘riser pipe’. Mud is used to maintain well pressure and wall stability, to cool

and lubricate the drill bit and to carry the rock chips (cuttings) generated during the drilling

process away from the cutting head to the platform. Here, the cuttings are partially cleaned and

the majority of drill mud re-used. Muds come in a variety of forms, dependent on their fluid base.

Amongst these are water based muds (WBM) and oil based muds (OBM). In the past, the bulk

of cleaned OBM cuttings were discharged to the seabed along with their residual oily mud

contamination. Extensive monitoring studies showed that this caused changes to the seabed via

a combination of smothering, organic enrichment and toxicity effects. These were seen to be

most severe close to discharging platforms where the ‘pile proper’ formed, but they commonly

extended up to a distance of 1 or 2 km. These discharges are no longer allowed.

Production

During production, large amounts of produced water (PW) are recovered with the

hydrocarbons. This is cleaned to very stringent standards and some is re-injected to maintain

reservoir pressure. The bulk, however, has traditionally been discharged to sea. As fields age

and as the amounts of oil remaining fall, the amounts of PW increase. The turn of the millennium

marked the time of maximum recovery of oil in the UK North Sea fields. So although the levels of

oil in produced water are very low, and despite improvements in technology which have tended

to reduce them, the overall total amount of oil discharged with the water by UK industry will

continue to rise in the next few years; it will then tail off as the industry declines. Increased

regulatory attention is therefore being focussed on the PW discharge, not least because in

addition to oil, it contains residues of naturally occurring heavy metals and radionuclides and oil

field chemicals.

Environmental hazards of petroleum refineries

Refineries are generally considered a major source of pollutants in areas where they are

located and are regulated by a number of environmental laws related to air, land and water.

Some of the regulations that affect the refining industry include the Clean Air Act, the Clean

Water Act, the Safe Drinking Water Act, CERCLA (i.e. Superfund: Comprehensive Environmental

Response, Compensation, and Liability Act), Emergency Planning and Community Right-to-

Know (EPCRA), OSHA (Occupational Safety & Health Administration), TSCA (Toxic Substances

Control Act), Oil Pollution Act and Spill Prevention Control and Countermeasure Plans. Here is a

breakdown of the air, water, and soil hazards posed by refineries:

• Air pollution hazards :

Petroleum refineries are a major source of hazardous and toxic air pollutants

such as BTEX compounds (benzene, toluene, ethylbenzene, and xylene). They are also

a major source of criteria air pollutants: particulate matter (PM), nitrogen oxides (〖NO〗_x),

carbon monoxide (CO), hydrogen sulfide (H_2 S), and sulfur dioxide (〖SO〗_2). Refineries

also release less toxic hydrocarbons such as natural gas (methane) and other light

volatile fuels and oils. Some of the chemicals released are known or suspected cancer-causing

agents, responsible for developmental and reproductive problems. They may

also aggravate certain respiratory conditions such as childhood asthma. Along with the

possible health effects from exposure to these chemicals, these chemicals may cause

worry and fear among residents of surrounding communities. Air emissions can come

from a number of sources within a petroleum refinery including: equipment leaks (from

valves or other devices); high-temperature combustion processes in the actual burning

of fuels for electricity generation; the heating of steam and process fluids; and the

transfer of products. Many thousands of pounds of these pollutants are typically emitted

into the environment over the course of a year through normal emissions, fugitive

releases, accidental releases, or plant upsets. The combination of volatile hydrocarbons

and oxides of nitrogen also contribute to ozone formation, one of the most important air

pollution problems in the United States.

Water pollution hazards :

Refineries are also potential major contributors to ground water and surface

water contamination. Some refineries use deep-injection wells to dispose of wastewater

generated inside the plants, and some of these wastes end up in aquifers and

groundwater. These wastes are then regulated under the Safe Drinking Water Act

(SDWA). Wastewater in refineries may be highly contaminated given the number of

sources it can come into contact with during the refinery process (such as equipment

leaks and spills and the desalting of crude oil). This contaminated water may be process

wastewaters from desalting, water from cooling towers, stormwater, distillation, or

cracking. It may contain oil residuals and many other hazardous wastes. This water is

recycled through many stages during the refining process and goes through several

treatment processes, including a wastewater treatment plant, before being released into

surface waters. The wastes discharged into surface waters are subject to state

discharge regulations and are regulated under the Clean Water Act (CWA). These

discharge guidelines limit the amounts of sulfides, ammonia, suspended solids and

other compounds that may be present in the wastewater. Although these guidelines are

in place, sometimes significant contamination from past discharges may remain in

surface water bodies.

• Soil pollution hazards :

Contamination of soils from the refining processes is generally a less significant

problem when compared to contamination of air and water. Past production practices

may have led to spills on the refinery property that now need to be cleaned up. Natural

bacteria that may use the petroleum products as food are often effective at cleaning up

petroleum spills and leaks compared to many other pollutants. Many residuals are

produced during the refining processes, and some of them are recycled through other

stages in the process. Other residuals are collected and disposed of in landfills, or they

may be recovered by other facilities. Soil contamination including some hazardous

wastes, spent catalysts or coke dust, tank bottoms, and sludges from the treatment

processes can occur from leaks as well as accidents or spills on or off site during the

transport process.

Refineries are also potential major contributors to ground water and surface

water contamination. Some refineries use deep-injection wells to dispose of wastewater

generated inside the plants, and some of these wastes end up in aquifers and

groundwater. These wastes are then regulated under the Safe Drinking Water Act

(SDWA). Wastewater in refineries may be highly contaminated given the number of

sources it can come into contact with during the refinery process (such as equipment

leaks and spills and the desalting of crude oil). This contaminated water may be process

wastewaters from desalting, water from cooling towers, stormwater, distillation, or

cracking. It may contain oil residuals and many other hazardous wastes. This water is

recycled through many stages during the refining process and goes through several

treatment processes, including a wastewater treatment plant, before being released into

surface waters. The wastes discharged into surface waters are subject to state

discharge regulations and are regulated under the Clean Water Act (CWA). These

discharge guidelines limit the amounts of sulfides, ammonia, suspended solids and

other compounds that may be present in the wastewater. Although these guidelines are

in place, sometimes significant contamination from past discharges may remain in

surface water bodies.

• Soil pollution hazards :

Contamination of soils from the refining processes is generally a less significant

problem when compared to contamination of air and water. Past production practices

may have led to spills on the refinery property that now need to be cleaned up. Natural

bacteria that may use the petroleum products as food are often effective at cleaning up

petroleum spills and leaks compared to many other pollutants. Many residuals are

produced during the refining processes, and some of them are recycled through other

stages in the process. Other residuals are collected and disposed of in landfills, or they

may be recovered by other facilities. Soil contamination including some hazardous

wastes, spent catalysts or coke dust, tank bottoms, and sludges from the treatment

processes can occur from leaks as well as accidents or spills on or off site during the

transport process.

References:

http://www.gov.scot/uploads/documents/ae09environmental.pdf

https://cfpub.epa.gov/ncer_abstracts/index.cfm/fuseaction/display.files/fileID/14522

http://www.gov.scot/uploads/documents/ae09environmental.pdf

https://cfpub.epa.gov/ncer_abstracts/index.cfm/fuseaction/display.files/fileID/14522

Written by

Phurich Prakhongwong

Edited by

Nipaporn Poonsawat

Phurich Prakhongwong

Edited by

Nipaporn Poonsawat